Kart/DC motor controller

|

DC motor

The DC motor is a Modelcraft RB350018-2A723R.

It is powered in 12 V and draws a maximal current of 0.7 A.

The control board hosts a dual full-bridge and a circuitry to create the switching dead-times and the direction of the current.

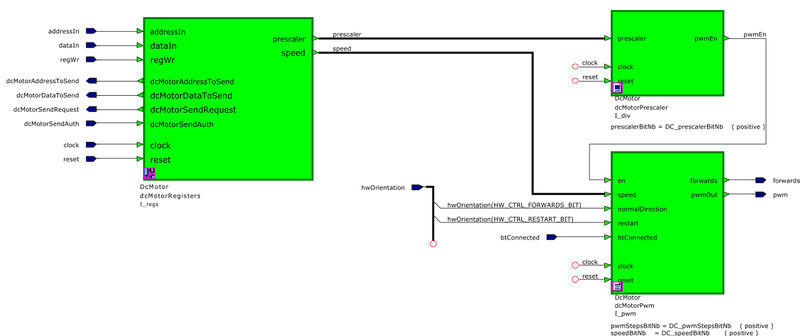

FPGA design

The DC motor controller has to control the Kart's propulsion both in forward and reverse.

For this, two signals are generated :

- A

pwmwith a controllable frequency whose duty-cycle is modified to control the speed - A

forwardssignal to drive either forward or backward.

The speed is set in the DC motor speed register, ranging from -15 to 15.

The frequency is given by the prescaler in the DC motor prescaler register with the

formula f = fclk / (PWMsteps * prescaler) = 10M / (16 * prescaler).

To begin with, the design environment has to be downloaded,

which contains the registers and events manager and an empty dcMotorPwm block which is to be completed.

Functionality

The block receives a speed signed number and has to drive the DC motor with a pwm and a forwards signal.

These signals are internally converted to two driving signals to control an H-bridge.

The mean amplitude of the DC motor's voltage is controlled by a Pulse Width Modulation (PWM):

- The

forwardssignal is derived from the sign of thespeedcontrol. - The

pwmsignal is derived from the absolute value ofspeed.

The PWM signal is implemented with the help of a free-running counter and a comparator. However, the power transistors cannot switch at too high frequencies

Because of this, the PWM period is limited to a certain value. This is achieved with the help of an en signal generated by a counter dividing the clock frequency. The counter only increments when this signal is '1'.

The minimal value of the PWM signal is studied in another part of the project.

The period of the en pulse train is set in the DC motor PWM period register

and given by the formula f = fclk / (PWMsteps * prescaler) = 10M / (16 * prescaler).

Hardware orientation

The mechanical design can either lead the Kart to drive forwards or backwards when a positive voltage is applied to the DC motor.

In order to cope with this, a setup signal, normalDirection, is provided to the block.

normalDirection being '1' means that a positive voltage applied to the DC motor lets the kart drive forwards.

The setup bit is configured in the hardware control register.

Bluetooth connection

When the Bluetooth connection is lost, the DC motor should not turn.

In order to cope with this, a control signal, btConnected, is provided to the block.

When btConnected is '0', the DC motor must stop.

If the btConnected then rises back to '1', the motor must NOT move until the speed register is modified.

Else the Kart would dangerously resume moving without the user being ready.

The BT connection bit is configured in the hardware control register.

Tests

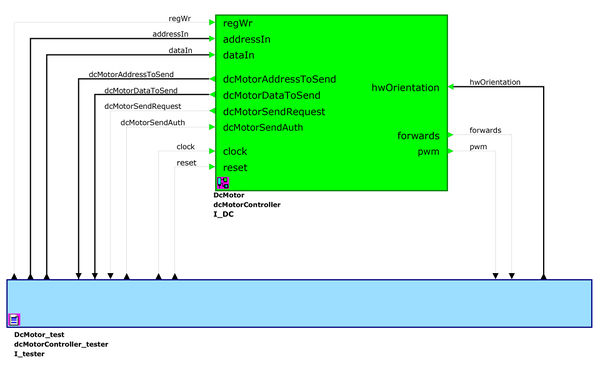

The DC motor functionality can be tested through the DCMotor_test -> dcMotorController_tb block.

The corresponding simulation layout file for Modelsim is available under $SIMULATION_DIR/DCMotor/dcMotorController.do. It will automatically run the simulation if it has not been modified.

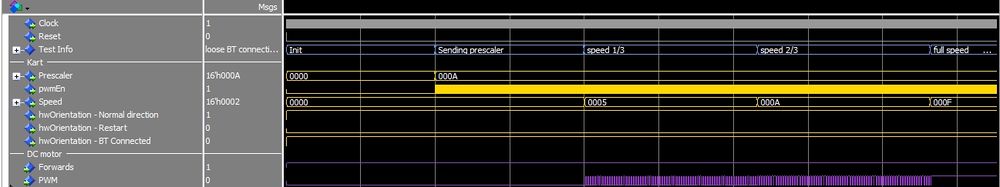

- The blue header shows which test is performed

- The yellow signals are those generated by the tester

- The purple signals are the one generated by your implementation

- You can add and remove signals at will, they will not interfere with the tests

Testing

The following tests are performed :

- The prescaler signal is set to 10

- Positive speed of 33, 66 and 100% are tested, expecting correct PWM and forwards = '1'

- Negative speed of 33, 66 and 100% are tested, expecting correct PWM and forwards = '0'

- The normalDirection is inverted

- Positive speed of 50 and 100% are tested, expecting correct PWM and forwards = '0'

- Negative speed of 50 and 100% are tested, expecting correct PWM and forwards = '1'

- Restart is held at '1' while normalDirection is inverted again, expecting PWM = '0' and forwards = '1'

- Restart is released, expecting correct PWM and forwards = '1'

- The BT Connection is lost, expecting PWM = '0'

- The BT Connection is retrieved, expecting PWM = '0' (by security, the Kart should not restart until receiving a new speed command)

- A speed of 0 is set, expecting PWM = '0' and forwards = '1' (in the real world, it is automatically done by the smartphone once reconnected)

- A speed of 50% is set, expecting correct PWM and forwards = '1'

The transcript window gives you details on if tests passed or not:

- For the PWM signal, you get

PWM OKorPWM Error. - For the forwards signal, you get

Direction OKorDirection Error.