Kart/stepper motor controller

|

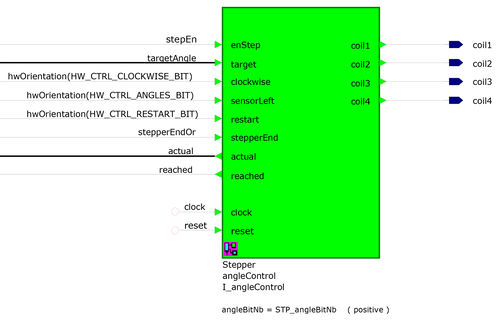

The kart's stepper motor controller module generates 4 coil driving signals and receives a stepper end input.

Stepper motor

Hardware

The stepper motor is a Nanotec SP3575M0906-A.

It has a step angle of 7.5°, and as such 48 steps per turn. It is attached to a 100:1 reductor, which leads to an output axis with 4800 steps per turn.

The DC/stepper control board hosts a dual full H-bridge to control the 4 coils of the stepper motor.

The end switch is connected between one of the FPGAs I/O with an internal pull-up enabled and the GND. The logic is internally reverted (i.e. a '1' is read when the switch is closed).

Connector

The cables are connected as follows:

Signal Color phase 1 white phase 2 blue phase 3 red phase 4 yellow GND brown, black

FPGA design

The stepper motor controller has to generate the 4 phases to turn the kart's steering wheels to the desired angle.

The target angle is set in the desired steering angle register.

To begin with, the design environment has to be downloaded.

It comprises the stepperMotorController block which contains the registers and events manager and an empty angleControl block which is to be completed.

Functionality

The block receives a targetAngle unsigned number and has to step the coils at each occurrence of the stepEn signal until the desired angle is reached.

The coils are controlled through the 4 outputs coil1 to coil4. When a '1' is applied, the corresponding coil is magnetized.

To control the stepper, one coil at a time should be magnetized, known as wave drive.

The switching frequency should also be chosen carefully. A frequency of 285 Hz is near the slip limit of the motor. The frequency is given by the formula : f = 100k / prescaler. A prescaler (clockDivider) of 400 (i.e. a frequency of 250 Hz) is a great first approach.

The steering angle, actual, is estimated with the help of a counter which increments or decrements each time the coils change.

It is joined with a logic signal, reached, telling if the desired angle has been reached.

This information is sent back to the controlling smartphone.

Zero position

A switch contact, providing the signal stepperEnd, has to be mechanically fitted on the kart in order set one end of the wheels' direction movement.

As soon as stepperEnd is '1', the stepper motor is stopped and the actual angle is reset.

With this, the steering motor will not try to turn further than what the kart's mechanical structure allows it to do in one of the directions.

In the other direction, it is the programmer's task not to request a too large target angle.

This also means that the angles are always considered as positive numbers, the zero position being given by the stepperEnd switch.

- In order to limit the current consumption, turn off the current in all the coils when the stepper motor is not turning any more.

- Make sure that both the first and the last pulse of the coil control signals have the same duration as all the others.

Hardware orientation

The mechanical design allows for the following variations:

- the

stepperEndswitch can be placed such as to detect the maximal steering angle either on the left or on the right side - switching the coil controls in the sequence

1 - 2 - 3 - 4 - 1 - 2 - …can result in the kart to turn either to the left or to the right

In order to cope with all possibilities, 2 setup signals are provided to the block:

-

sensorLeftbeing '1' means that thestepperEndswitch has been placed such as to react when the wheels are oriented to the maximal steering angle on the left side -

clockwisebeing '1' means that the sequence1 - 2 - 3 - 4 - 1 - 2 - …lets the steering turn to the right

The corresponding setup bits are configured in the hardware control register.

Initial position

The hardware control register also contains the bit restart indicating that the stepper motor has to turn all the way back until presswing the stepperEnd.

This has to be sent by the remote control smartphone after a successful Bluetooth pairing, together with the appropriate sensorLeft and clockwise setup bits, in order for the FPGA hardware to discover the zero angle position.

Obviously, this should only be done after the Stepper motor period register has been set to a proper value.

Restarting to the zero position can also be a help if too much current has been drawn from the batteries and the FPGAs' power has sunk in a way that they have performed a reset.

The restart signal stays high until the stepperEnd is pressed or is reset by the smartphone.

Thus, when detecting the signal, one must enter a restart state and move until the stepperEnd is pressed.

If the switch is already on, it will stay high during only one clock period.

Tests

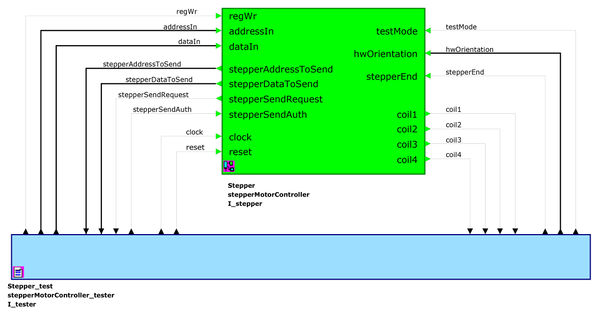

The Stepper motor functionality can be tested through the StepperMotor_test -> stepperMotorController_tb block.

The corresponding simulation layout file for Modelsim is available under $SIMULATION_DIR/Stepper/stepperMotorController.do. It will automatically run the simulation if it has not been modified.

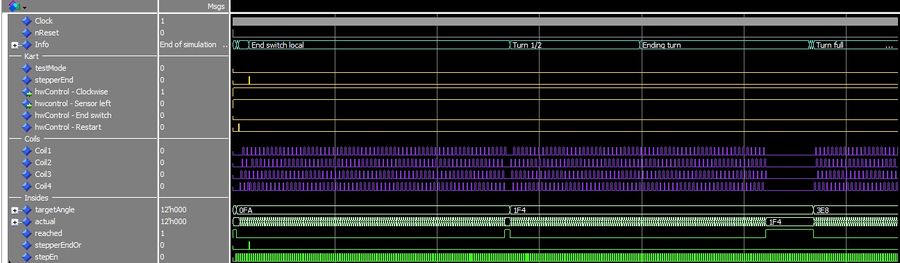

- The blue header shows which test is performed

- The yellow signals are those generated by the tester

- The purple signals are the one generated by your implementation

- The green signals are internal ones

- You can add and remove signals at will, they will not interfere with the tests

Testing

The following tests are performed :

- The prescaler is set, outputting pulses on stepEn

- The restart signal pulses (both one pulse or constant '1' are valid), expecting the coils to turn as 4-3-2-1-4...

- The restart signal is released, expecting the coils to keep turning

- The stepperEnd is pressed, expecting the coils to stop

- A target of 250 is set, expecting the coils to move in order 1-2-3-4-1...

- The reached signal should be '1' when 250 pulses have been made

- A target of 500 is set, expecting same behavior as before

- The target suddenly changes back to 0, expecting the coils to move in the reversed sequence of 4-3-2-1-4...

- The reached signal should be '1' when actual reaches 0

- A target of 250 is set

- A new restart is issued as before, while the sensor left signal being set to '0', expecting the coils to turn as 1-2-3-4-1...

- A target of 250 is set, expecting the coils to move in order 4-3-2-1-4...

- The reached signal should be '1' when 250 pulses have been made

- A target of 0 is set, expecting the coils to move as 1-2-3-4-1...

- The reached signal should be '1' when actual reaches 0

- A new restart is issued as in the beginning after trying to reach a target of 500, expecting the coils to turn as 4-3-2-1-4...

- The hwControl - end switch (emulated stepperEnd) is pressed, expecting the coils to stop

The transcript window gives you details on if tests passed or not:

- For the Coil1...4 signals, you get

Coil direction OKorCoil direction error. - For the reached signal, you get

Reached flag OKorReached flag error. - For the actual signal, you get

Position readback OKorPosition readback error.